Get to know about us

Skylight Graphics Industries is the in-house manufacturing of anilox rollers. Our first thought is to create and manufacture quality materials to fulfill the customer requirements. We produce the best quality rollers which are consistently overseen and supervised by our well experienced experts.

Skylight Graphics Industries has been committed to serving the printing & coating industry through innovation. Now the world’s largest anilox solutions provider offers these benefits as part of our commitment to technical innovation and the development of the most consistent anilox solutions on the market today.

We believe in building a sustainable partnership with each of our clients through truly individual service. Some of the ways we do this are by offering opportunities to educate your workforce on optimum care of your roller, suggesting the best cleaning solution, or providing detailed advice on how to customize your print operations for peak performance.

Anilox rollers manufacturing specialty

Dynamic balance inspection and dynamic balancing to eliminate vibration

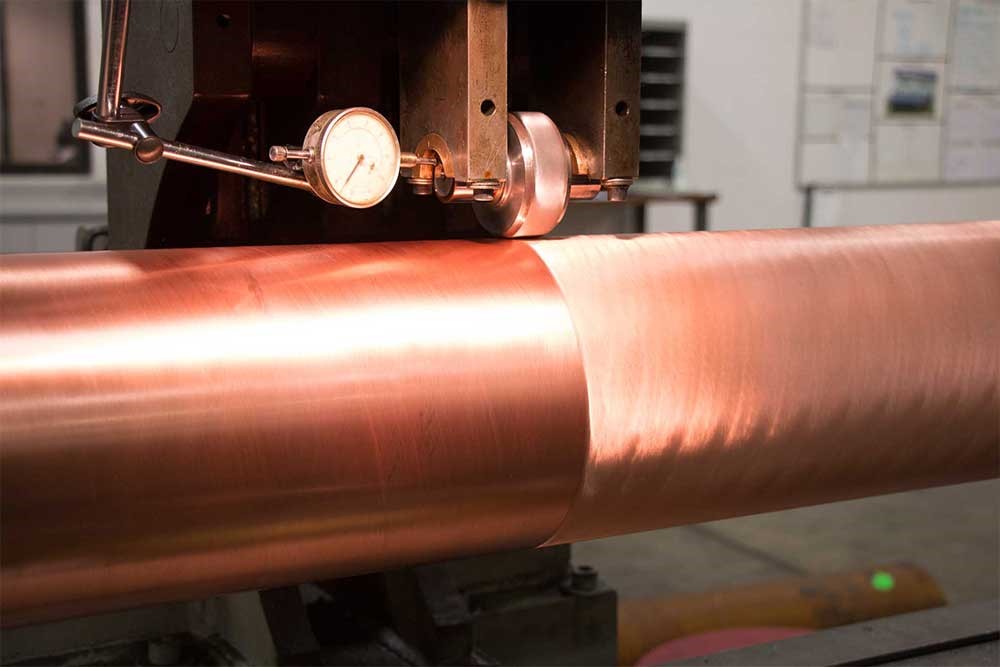

Copper Plating of required thickness & hardness as per cell Pattern & Depth.

Machining & Grinding on High Precision Lathe & Grinding.

All Dimensions within very close tolerance with turning on high precision lathe.

Uniform Depth.

We can Produce Maximum Size anilox roller (Diameter 350 mm up to 2400 mm face Length).

Available Mesh Screen for engraving anilox roller 20 to 400 LPI.

lnk deposition shall be uniform, throughout the engraved length of the cylinder

We can select the proper LPI and engraving depth if we are given the percentage of solid content of the chemical/ink to be coated along with the dry GSM deposit desired on the substrate.

We can engraving the cylinder having up to 1 GSM to 20 GSM