Anilox Roller

The Anilox roll is called the “heart of the printing press” and its effect directly affects the fineness and uniformity of the print.

The flexo printing/coating process depends upon the precise controlled transfer of a liquid ink, varnish or coating. An anilox roll is simply a metering roll designed to consistently supply a uniform and measurable volume of ink onto the image carrier. Anilox roll is considered to be the heart of the flexographic press.

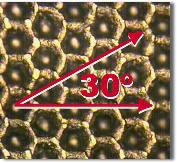

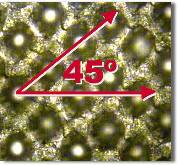

There are three main cell characteristics important to understand including:

1. The angle of the cells (60°, 45°, 30°, etc.)

2. The carrying capacity of the cell (or cell volume)

Cell volume is the capacity of the engraved surface in a square inch, expressed in Billion Cubic Microns (BCM).

Higher volume translates to higher solid ink density, more color or a heavier coating thickness. Lower volumes apply thinner ink films directly associated with higher print quality and process efficiency. Anilox cell volume changes over time, due to wear, plugging and cleaning procedures. Dirty or plugged cells are temporary and correctable to restore cell volume and color. Wear is irreversible and permanent resulting in weaker or less color due to lower volume.

3. The number of cells per linear inch or line screen ( LPI )

Line screen indicates the number of cells per linear inch on an anilox roll, and is a major component when specifying an anilox roll. Different printing applications require different line screen counts.

Selection of parameters and types of engraving

Before selecting parameters of an anilox roll, the following factors should be taken into account:

- Application of the anilox roll.

- Properties of inks and printed materials.

- Type and characteristics of the printing machine.

- Printing requirements and technical specifications of the cliché.

- Availability of a doctor blade system.

Use & Care Anilox Rollers

- At running speeds, never let rolls run dry.

- Use suggested cleaning chemicals for cleaning.

- When printing unit is not in use, separate rolls as soon as possible and wash all the components especially anilox roll with brass brush and recommended cleaning chemicals.

- Flaking chrome indicate damage to fountain roll.

- (A minute portion of moist ink at the very bottom of cells may penetrate the chrome if given enough time and will corrode the steel base under the surrounding chrome and cause chips of chromium to flake-off.)

- Transport with journals and roller face protected.

- Check for roller wear with 14 power magnifying glass. Wear is seen by increase in shine on roll and loss of color strength in the print.

- Change blades regularly.

- Change end seals regularly.

- Maintain correct manufacturers recommended viscosity.

- Use a Coating Filter to prevent excessive wear (magnet filter).

- Perform regular Anilox roller audits.

- Cover the rollers when not in use to prevent damage.